In the previous posts I've described a simple Geiger–Müller counter and various experiments with this device. Today I would like to present Arduino project to communicate with a Geiger-Muller counter, gather data and present it to the user. The device is based on Arduino Uno, Nokia 5110 LCD and homemade shield.

Currently it's possible to show two layouts: bar graph of the pulses in one minute interval and histogram of the gathered data. Both graphs are auto-ranging in Y axis. On the top of the pulse graph is visible also a numeric value of the last sample. The length of the histogram data is 4 minutes, the amount of bins is calculated automatically.

Below is visible layout with pulses per quant of time and histogram of them. You can clearly observe Gaussian distribution on the second image.

Hardware

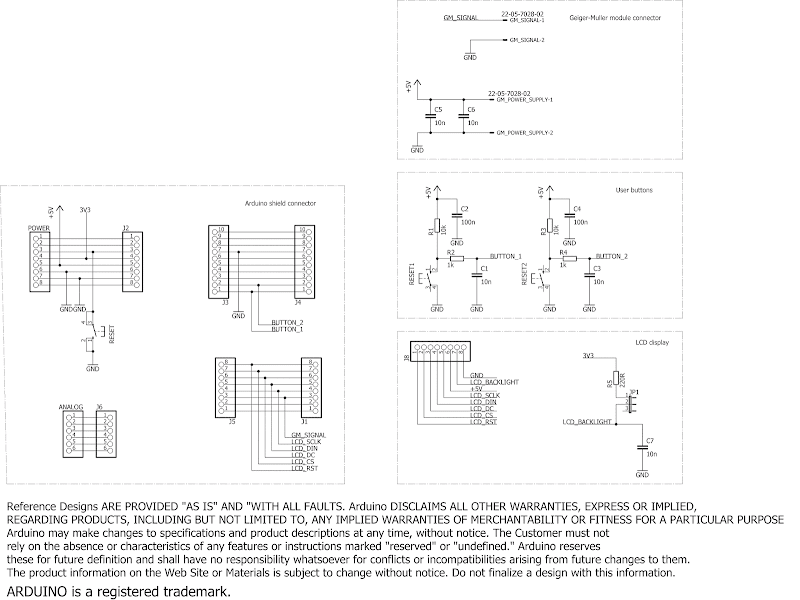

I didn't want to place all of the connections and input PCB dimensions of a shield, so I've used as a base one of freely available shields and modified it to my needs - I've left the licence disclaimer unmodified. Unfortunately, I wrongly connected LCD, that's why the LCD looks like rotated 180 degrees. Anyway, it still works and I don't plan to make a new PCB to fix it.

I tried to make the code reusable in my other projects so the structure may look overcomplicated, but I think it's as it should be.

Software

Followed 3rd party librairies needs to be installed, to install them in Arduino IDE go to sketch -> Include Library -> Manage Libraries then type library name and proceed with installation.

- Adafruit-GFX-Library

- Adafruit-PCD8544-Nokia-5110-LCD-library

static GMCounter<4 * 24> hourGMCounter;

This will create an object with this class with a buffer for 4*24 samples. I think, that it's quite cool.

There's a lot of commented out code in the main function, it was used to test parts of the program as it was developed. I didn't remove it because it still can be used if I will add new features.

Download.

The source code and Eagle files of the project is available on the GitHub, feel free to download and try it if you're interested in this area of physic.