It’s 2024, and technologies from web development have made their way into the embedded world too-things like containerization, automated deployment, and more. This project is a small hat for the Raspberry Pi that gathers measurements for temperature, humidity, and air pressure. I created it as a learning tool to explore these concepts while using Docker, Ansible, and Grafana.

The picture below shows the hat. I thought it was so simple that I wouldn't make any mistakes during assembly, but, as usual, I did. The PCB turned out to be too long and collides with the USB port of the Raspberry Pi. That’s why I had to connect it using jumper wires. It works, but it doesn’t look very cool.

I didn’t choose these sensors for any particular reason—they were just parts I had on hand from the good pre-COVID times when software components and sensors were still cheap :)

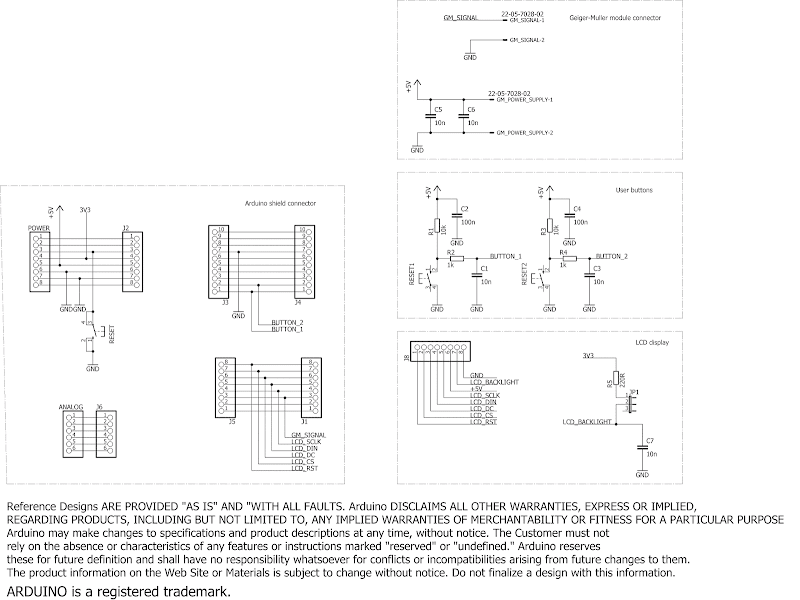

The circuit is shown below. It consists of two sensors that communicate via I2C with the Raspberry Pi, along with a small LCD that also uses I2C. The LCD displays the measurement data as well.

Some people say that if your Raspberry Pi starts slowing down, it’s a sign that the SD card is about to fail, so it’s time to back up. I noticed mine was slowing down, checked the kernel logs, and everything looked fine, so I figured I was safe. The next day, the SD card was dead. So yeah, it’s definitely a good idea to back up in such cases.

This happened before I got into Docker and all the containerization stuff, so I was just developing scripts directly on the Raspberry Pi—and I think I lost them. It’s funny how I started this project to learn about containerization as a reliable way to deploy code, and I kicked things off with such a fail!

From the software point of view, the project will consist of three components:

- Python software for gathering data from the sensors

- InfluxDB for storing the measurements

- Grafana for data analysis and presentation

I think each of these components will have its own Docker container. In addition, I’ve already created a Docker container for cross-compilation (since my PC has x86 architecture and the Raspberry Pi uses ARM architecture). It was quite a struggle to get that working. I plan to automate the installation using Ansible.

If you’re interested in the details, the full project is available on GitHub and Hackaday. Feel free to explore, make your own modifications, and maybe even improve on what I’ve done. And if you find it useful, don’t forget to share it!